Nickel Metal Hydride (NiMH) batteries are a mature and widely adopted rechargeable battery technology that continues to play an important role in global energy storage systems. Even in 2026, NiMH batteries remain highly relevant across industries such as medical equipment, renewable energy, industrial electronics, and hybrid transportation.

Unlike many newer battery chemistries that prioritize energy density above all else, NiMH batteries offer a balanced combination of safety, cost efficiency, durability, and temperature tolerance, making them a long-term solution rather than a short-lived trend.

This comprehensive guide will explore:

The iternal electrochemical structure that enables long cycle life

Key performance specifications compared with lithium-ion alternatives

Real-world industries where NiMH still outperforms newer technologies

Best maintenance practices to extend service life

Technical benchmarks based on modern industry standards

As of 2026, advanced NiMH batteries can achieve:

Energy density up to 140 Wh/kg in industrial-grade cells

Operating temperature range from -40°C to 60°C

Lifecycle cost approximately 40% lower than most lithium-based systems

To fully understand why NiMH batteries remain competitive, it is essential to begin with their fundamental design principles.

Electrochemical Composition

A nickel metal hydride battery consists of two primary electrodes. The positive electrode is made from nickel oxyhydroxide (NiOOH), while the negative electrode is constructed from a hydrogen-absorbing metal alloy. This alloy typically includes rare earth elements combined with nickel and stabilizing metals such as titanium, zirconium, or cobalt.

The core operating mechanism is based on the reversible storage and release of hydrogen ions within the metal alloy. During charging, hydrogen ions are absorbed into the alloy structure. During discharge, those hydrogen ions are released and participate in the electrochemical reaction that generates electrical energy.

This hydrogen storage mechanism is the defining feature that separates NiMH from older nickel-cadmium technologies.

Electrolyte System

NiMH batteries use an alkaline electrolyte, most commonly potassium hydroxide (KOH). The electrolyte does not participate directly in energy storage but acts as a highly efficient ion conductor between the positive and negative electrodes.

The alkaline environment supports fast ion transport, stable internal resistance, and long-term chemical stability, which contributes to the overall reliability of NiMH cells across thousands of charge-discharge cycles.

Voltage and Capacity Characteristics

The nominal voltage of a single NiMH cell is approximately 1.2 volts, which is lower than lithium-ion cells but higher than many legacy chemistries. This voltage remains relatively stable throughout most of the discharge curve, making NiMH suitable for devices that require consistent output.

In terms of capacity, modern NiMH batteries typically range from 1000mAh to over 3000mAh, depending on physical size, electrode formulation, and intended application. Larger industrial formats can achieve even higher capacities for energy storage systems and backup power solutions.

Charging Rate and Physical Dimensions

NiMH batteries support moderate charging rates, usually between C/10 and C/3. For example, a 2000mAh battery can safely charge between 200mA and 600–700mA depending on charger design and thermal management.

NiMH batteries are manufactured in a wide range of standardized sizes, including AAA, AA, C, D, as well as custom industrial formats. This versatility allows them to integrate into both consumer electronics and large-scale industrial systems.

Self-Discharge Behavior

One of the inherent limitations of NiMH technology is its relatively high self-discharge rate. Traditional NiMH batteries may lose 1% to 5% of their stored energy per day when left unused.

Although newer low-self-discharge variants significantly reduce this issue, self-discharge remains a key consideration for applications involving long storage periods or emergency equipment.

High energy density for nickel-based systems

NiMH batteries offer significantly higher energy density than older nickel-cadmium batteries, allowing more energy to be stored in the same physical space.

Long cycle life and rechargeability

NiMH batteries can withstand hundreds to thousands of full charge cycles while maintaining usable capacity, making them ideal for reusable energy systems.

Environmentally safer materials

NiMH batteries do not contain toxic cadmium, reducing environmental impact during manufacturing, disposal, and recycling.

Enhanced safety profile

Compared to many lithium-based batteries, NiMH has a much lower risk of thermal runaway, fire, or explosion under normal operating conditions.

Lower long-term cost

Due to long lifespan and relatively low production cost, NiMH offers strong economic value over time, especially for industrial and commercial systems.

High self-discharge rate

Without regular charging, NiMH batteries lose stored energy faster than most lithium batteries.

Memory effect and voltage drop

Although less severe than older chemistries, partial charging over long periods can still reduce effective capacity. Voltage sag under high load can also occur.

Sensitivity to temperature extremes

High temperatures accelerate degradation, while very low temperatures reduce discharge efficiency.

Limited fast-charging capability

NiMH batteries generally require longer charging times and cannot tolerate aggressive fast-charging without advanced control systems.

Lower nominal voltage

The 1.2V output requires multiple cells in series for high-voltage applications, increasing system complexity.

Despite rapid advancements in lithium technologies, NiMH remains dominant in several critical sectors due to its exceptional reliability, thermal stability, and predictable aging behavior.

In hybrid transportation systems, NiMH continues to be favored because of its ability to handle frequent shallow charge cycles without accelerated degradation. Industrial operators value NiMH for its long-term reliability under real-world conditions rather than laboratory performance metrics.

NiMH is also widely used in aerospace, railway signaling systems, defense electronics, and medical infrastructure, where failure tolerance and safety margins outweigh raw energy density.

Consumer Electronics

NiMH batteries are commonly used in digital cameras, handheld gaming devices, remote controls, wireless keyboards, and portable audio players. Their stable voltage output and reusability make them ideal for medium-drain electronics.

Power Tools

Cordless drills, electric screwdrivers, and inspection tools often rely on NiMH for dependable energy delivery and long service life.

Medical Equipment

NiMH batteries power critical medical devices such as infusion pumps, oxygen concentrators, portable diagnostic equipment, and monitoring systems, where safety and reliability are essential.

Hybrid Vehicles

Hybrid drive systems use NiMH for energy buffering, regenerative braking storage, and auxiliary power, benefiting from high cycle tolerance.

Emergency Lighting and Backup Power

NiMH is widely used in emergency exit signs, backup lighting, and uninterruptible power supplies due to predictable discharge behavior and low fire risk.

Renewable Energy Storage

Small-scale solar systems, off-grid wind installations, and portable energy storage stations use NiMH as a cost-effective and temperature-tolerant solution.

Outdoor and Portable Equipment

Flashlights, camping lamps, communication radios, and emergency kits often rely on NiMH batteries for durability and consistent performance.

Electric Mobility Devices

Some electric bicycles, scooters, and mobility aids still use NiMH, especially in regions where cost and environmental durability are prioritized.

1. Energy Density

Lithium-ion provides higher energy density, but NiMH offers more stable performance under fluctuating loads.

2. Self-Discharge Rate

NiMH loses energy faster when idle, while lithium-ion retains charge longer.

3. Temperature Tolerance

NiMH operates effectively in both extreme cold and high heat, outperforming most lithium chemistries in harsh environments.

4. Cycle Life

Industrial-grade NiMH can exceed 1500 cycles, often outlasting consumer lithium cells.

5. Charging Speed

Lithium-ion supports faster charging, while NiMH requires controlled charging to avoid overheating.

6. Voltage Behavior

NiMH maintains a stable voltage curve, which benefits devices sensitive to voltage fluctuations.

7. Recycling and Sustainability

Nickel recovery rates are significantly higher than lithium, making NiMH easier and cheaper to recycle at scale.

Are NiMH Batteries Better Than Lithium?

For high-energy applications, lithium-ion offers superior energy density. However, NiMH excels in safety-critical systems where fire risk, thermal stability, and long-term reliability are more important than compact size.

How Long Do NiMH Batteries Last?

Consumer-grade NiMH batteries typically last 2–3 years, while industrial systems can exceed 10 years with proper maintenance.

Best practices include:

Performing periodic full discharge cycles

Storing at partial charge in cool environments

Using intelligent chargers with temperature and voltage monitoring

Can NiMH Batteries Explode?

NiMH batteries have a significantly lower thermal runaway risk compared to lithium-ion. Overcharging can cause leakage or venting, but catastrophic failure is rare.

Why Are NiMH Used in Hybrid Systems?

NiMH is preferred in hybrid systems because it:

Handles frequent charge-discharge cycles well

Offers predictable degradation

Has extremely low fire risk

Maintains performance across wide temperature ranges

Do NiMH Batteries Work in Cold Weather?

Yes. NiMH retains most of its usable capacity even at -20°C to -40°C, making it suitable for cold climates, polar research stations, and outdoor monitoring equipment.

While lithium-ion dominates headlines, NiMH remains one of the most reliable, safest, and economically sustainable battery technologies available today.

For applications where long service life, thermal stability, environmental safety, and predictable performance matter more than maximum energy density, NiMH continues to be not just relevant—but often the superior choice.

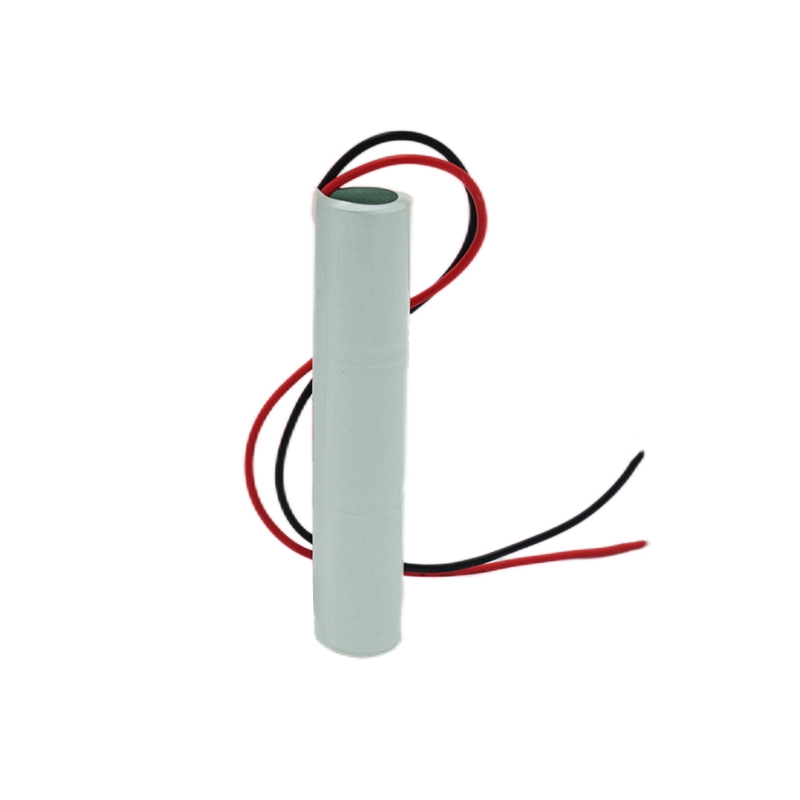

Ni-MH Battery C4700mAh 3.6V

Ni-MH Battery C4700mAh 3.6V Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V

Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V Ni-Cd Battery Pack D4000mAh 3.6V

Ni-Cd Battery Pack D4000mAh 3.6V Ni-Cd Battery Pack C2500mAh 3.6V

Ni-Cd Battery Pack C2500mAh 3.6V NICAD Battery Pack AA900mAh 3.6V

NICAD Battery Pack AA900mAh 3.6V LiFePO4 IFR18650 1600mAh 3.2V

LiFePO4 IFR18650 1600mAh 3.2V LiFePO4 IFR18650 1600mAh 6.4V

LiFePO4 IFR18650 1600mAh 6.4V Ni-MH Battery C4000mAh 3.6V

Ni-MH Battery C4000mAh 3.6V E-bike Battery 48V 10Ah JL-1

E-bike Battery 48V 10Ah JL-1 E-bike battery 48V 10Ah Qing Tian

E-bike battery 48V 10Ah Qing Tian