In the rapidly evolving field of battery technology, different cell structures play a decisive role in determining performance, safety, cost, and application suitability. Among all mainstream lithium battery formats, cylindrical cells, prismatic cells, and pouch cells are the three most widely used designs across consumer electronics, electric vehicles, industrial equipment, and energy storage systems.

Each cell type has its own structural characteristics, manufacturing logic, and performance advantages. Understanding the differences between them is critical for system designers, product engineers, and energy storage buyers.

This article provides a comprehensive technical breakdown of:

Structural design principles of each cell type

Core advantages and limitations

Real-world application scenarios

Performance differences in energy density, safety, and lifespan

Practical guidance for selecting the right battery format

By the end of this guide, you will clearly understand which battery cell type is most suitable for different industries and use cases in 2026.

Cylindrical cells are one of the most mature and widely adopted battery formats in the global market. As the name suggests, these cells feature a tubular metal casing, with electrode materials wound into a spiral “jelly roll” structure inside.

Common cylindrical formats include 18650, 21700, and 4680, which are named based on their physical dimensions. The cylindrical structure allows for standardized mass production and high mechanical strength.

Mature and cost-efficient manufacturing

Cylindrical cells have been produced at industrial scale for over two decades. Their production lines are highly automated, resulting in excellent consistency, high yields, and lower unit costs compared to other cell formats.

High energy density

Due to their optimized internal winding structure, cylindrical cells achieve high gravimetric and volumetric energy density. This allows them to store a large amount of energy in a compact space, making them suitable for high-capacity devices.

Excellent thermal management

The round shape naturally promotes heat dissipation. Heat spreads evenly across the surface, reducing hotspots and improving safety under high current loads.

Strong mechanical durability

The rigid metal casing provides strong protection against physical impact, vibration, and compression. This makes cylindrical cells highly reliable in automotive, industrial, and outdoor environments.

Easy modular integration

Standardized dimensions allow easy packing into battery modules, simplifying system design and maintenance.

Limited form factor flexibility

The fixed cylindrical shape limits design freedom. It is difficult to fully utilize space in slim or irregularly shaped devices.

Internal mechanical stress

The internal spiral structure can experience mechanical stress over long-term cycling, potentially affecting electrode alignment.

Smaller single-cell capacity

Due to radial heat dissipation limits, individual cylindrical cells usually have lower capacity than large prismatic or pouch cells. This means large battery packs require thousands of cells, increasing system complexity.

Consumer electronics such as laptops and cameras

Electric vehicles and electric motorcycles

Cordless power tools

Portable power stations

Industrial robots and automation equipment

Prismatic cells are characterized by their flat rectangular shape. Internally, the electrode layers are stacked rather than wound, and the entire structure is enclosed in a rigid aluminum casing.

This design focuses on maximizing space utilization while maintaining mechanical strength.

Superior space utilization

The rectangular structure allows battery packs to be arranged tightly with minimal wasted space, making prismatic cells ideal for compact systems.

High packing efficiency

Stacked electrode layers enable better volumetric efficiency inside battery modules, which is particularly beneficial for large-scale energy storage systems.

Simplified structural design

Prismatic cells reduce the need for complex mechanical frameworks inside battery packs, leading to simpler system architecture.

Improved system-level safety

The rigid casing provides better protection against external impact compared to pouch cells.

Limited shape flexibility

The rigid rectangular format cannot easily adapt to curved or irregular product designs.

Higher sensitivity to swelling

Internal gas generation can cause cell swelling, which may stress the casing and affect long-term reliability.

Lower standardization

Prismatic cells come in many custom sizes, which complicates automation and quality consistency across manufacturers.

Electric vehicles and electric buses

Stationary energy storage systems

Solar energy storage

Medical imaging equipment

Industrial automation systems

Grid-level backup power

Prismatic cells dominate large battery systems because they balance energy density, structural stability, and system integration efficiency.

Pouch cells represent the most flexible battery cell design. They use no rigid metal casing and instead rely on an aluminum-polymer laminated film to encapsulate the internal electrode stack.

This structure minimizes inactive materials and maximizes usable energy.

Highly customizable form factor

Pouch cells can be produced in almost any shape or thickness, enabling ultra-thin and lightweight battery designs.

Lightweight structure

Without metal casing, pouch cells are significantly lighter than cylindrical or prismatic cells of the same capacity.

High energy density

The reduced packaging mass increases overall energy density, especially at the system level.

Lower explosion risk

In abnormal conditions, pouch cells tend to swell and vent rather than violently rupture.

Low mechanical protection

Without rigid casing, pouch cells are more vulnerable to puncture, compression, and vibration.

Poor structural stability

External frames and compression structures are required in battery packs.

Standardization challenges

Custom dimensions and reliance on specialized packaging materials increase manufacturing complexity and cost.

Smartphones and tablets

Wearable electronics

Power banks and portable chargers

Electric vehicles and electric bikes

Drones and UAVs

Portable medical devices

Residential energy storage systems

Pouch cells dominate lightweight, space-constrained, and design-driven products.

Physical Structure

Cylindrical cells use a wound spiral structure inside a metal tube.

Prismatic cells use stacked layers inside a rigid rectangular casing.

Pouch cells use stacked layers inside a flexible laminated film.

Form Factor and Design Freedom

Cylindrical cells are highly standardized but inflexible.

Prismatic cells offer moderate flexibility with strong structure.

Pouch cells provide maximum design freedom.

Energy Density and Performance

Cylindrical cells achieve high consistency and stable performance.

Prismatic cells balance energy density and system integration.

Pouch cells deliver the highest system-level energy density.

Manufacturing Complexity

Cylindrical cells require complex winding equipment.

Prismatic cells use stacking and laser welding processes.

Pouch cells use lamination and sealing processes.

Mechanical Durability and Safety

Cylindrical cells offer the strongest mechanical protection.

Prismatic cells provide medium structural support.

Pouch cells require external reinforcement.

What Is a Prismatic Battery Cell?

A prismatic battery cell is a rectangular lithium battery with stacked internal electrodes. This design improves space utilization and simplifies large battery pack assembly.

Are Prismatic Cells Better Than Pouch Cells?

Prismatic cells are mechanically stronger and easier to integrate into large systems. Pouch cells offer higher energy density and lighter weight. The choice depends on whether safety or compactness is the primary goal.

How to Extend the Lifespan of Prismatic Cells?

To maximize lifespan:

Keep operating temperature between 20–40°C

Avoid deep discharges below 20%

Use controlled charging rates

Prevent long-term overcharging

Proper thermal and charge management can extend prismatic cells beyond 2,000 cycles.

There is no single “best” battery cell type for all applications.

Cylindrical cells are best for standardization, durability, and mass production.

Prismatic cells are ideal for large battery systems requiring strong structure and high space utilization.

Pouch cells excel in lightweight, compact, and design-focused products.

The optimal choice depends on:

Application environment

Safety requirements

Energy density targets

System size and cost constraints

In modern energy systems, battery performance is determined not only by chemistry, but also by cell structure, thermal design, and system integration strategy. Choosing the right cell format is one of the most critical decisions in any battery-based product.

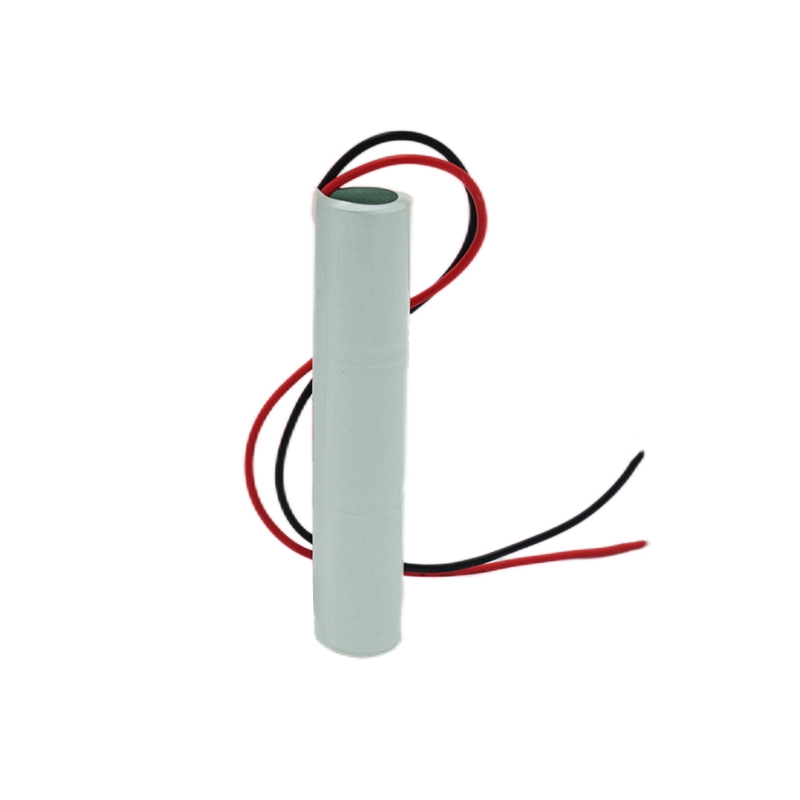

Ni-MH Battery C4700mAh 3.6V

Ni-MH Battery C4700mAh 3.6V Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V

Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V Ni-Cd Battery Pack D4000mAh 3.6V

Ni-Cd Battery Pack D4000mAh 3.6V Ni-Cd Battery Pack C2500mAh 3.6V

Ni-Cd Battery Pack C2500mAh 3.6V NICAD Battery Pack AA900mAh 3.6V

NICAD Battery Pack AA900mAh 3.6V LiFePO4 IFR18650 1600mAh 3.2V

LiFePO4 IFR18650 1600mAh 3.2V LiFePO4 IFR18650 1600mAh 6.4V

LiFePO4 IFR18650 1600mAh 6.4V Ni-MH Battery C4000mAh 3.6V

Ni-MH Battery C4000mAh 3.6V E-bike Battery 48V 10Ah JL-1

E-bike Battery 48V 10Ah JL-1 E-bike battery 48V 10Ah Qing Tian

E-bike battery 48V 10Ah Qing Tian