Battery cycle life represents the total number of complete charge and discharge cycles a battery can undergo before its capacity falls to around 80% of its original rating. Every charge and discharge induces minor chemical and structural changes in the electrodes. Over hundreds or thousands of cycles, these changes gradually accumulate, increasing internal resistance and reducing the number of active lithium ions available for energy storage.

For instance, a LiFePO4 cell rated for 3,000 cycles means it can undergo approximately 3,000 full charge and discharge cycles under controlled temperature and voltage conditions before the usable capacity diminishes to 80%.

Cycle life and runtime are two distinct concepts that are often misunderstood:

Cycle Life: Measures the total number of times a battery can be charged and discharged before its capacity degrades. Factors influencing cycle life include depth of discharge (DoD), temperature, and charge/discharge rates.

Runtime: Refers to how long a single charge can power a device, depending on battery capacity and the load applied.

A long runtime does not necessarily equate to a long cycle life. Deep discharges extend the duration per use but shorten the overall number of cycles. For long-term energy storage or solar applications, managing DoD is more critical than maximizing runtime.

LiFePO4 batteries are built on a highly stable olivine crystal structure, which naturally resists structural collapse and oxygen release, giving them superior longevity compared to many other chemistries. However, several factors determine the actual cycle life achieved in practice:

1. Depth of Discharge (DoD)

The deeper a battery is discharged in each cycle, the fewer total cycles it will last. Fully depleting a LiFePO4 battery places stress on lithium-ion movement, accelerating degradation processes within the electrodes.

For optimal longevity, it is recommended to operate LiFePO4 batteries between 20% and 80% of their full charge. This approach can effectively double their usable lifespan.

2. Charge and Discharge Rates (C-rate)

The C-rate measures current relative to battery capacity. High C-rates generate more heat and mechanical stress, which accelerates aging. Slow charging and discharging help maintain uniform lithium diffusion, reducing strain on the cell and extending cycle life. Using a battery management system (BMS) to control current and balance cell voltages is essential.

3. Operating Temperature

Temperature strongly affects battery chemistry and performance. High temperatures accelerate electrolyte breakdown and SEI layer thickening, while very low temperatures increase the risk of lithium plating and capacity loss. The ideal operating range is typically between 10°C and 35°C. Batteries exposed to prolonged heat above 60°C may experience permanent structural damage.

4. Material Quality and Manufacturing

Cycle life is also influenced by the quality of materials and assembly:

Purity and uniformity of LiFePO4 active material

Electrolyte composition and additives

Cell formation and balancing during production

Precision in electrode coating and assembly

High-quality manufacturing ensures consistent performance and longer-lasting batteries.

Deep cycle LiFePO4 batteries are specifically designed to handle repeated deep discharge and recharge cycles while maintaining stable performance. They feature thicker electrodes and optimized electrolytes, which provide structural integrity and consistent voltage output across the entire discharge curve.

Common applications include:

Solar energy storage systems

Marine and RV power systems

Electric vehicles and e-mobility solutions

Backup power systems and UPS units

Unlike starter batteries, deep cycle LiFePO4 cells sustain voltage stability throughout discharge, ensuring predictable performance over thousands of cycles.

The depth of discharge directly affects total energy throughput. Using a smaller fraction of total capacity per cycle reduces stress on the battery, significantly extending its lifespan. Managing DoD is one of the most effective ways to maximize the total usable energy and overall cycle life of LiFePO4 batteries.

LiFePO4 batteries maintain a relatively flat voltage curve over most of their discharge cycle. This property provides stable energy delivery but makes precise estimation of state of charge (SOC) from voltage alone less accurate. A BMS is recommended to monitor SOC and ensure cells operate within safe limits.

Reliable testing involves simulating real-world operating conditions:

Continuous cycle life tests to monitor capacity retention

Impedance measurements to detect internal resistance growth

Temperature cycling to test reliability in extreme conditions

Safety and abuse tests such as overcharge, short-circuit, and mechanical stress

These procedures provide insight into battery longevity and help optimize design for maximum cycle life.

To achieve the longest possible service life from LiFePO4 batteries:

Keep DoD below 80% for general use and below 50% for critical systems

Charge slowly whenever possible, ideally at half the rated C-rate

Avoid charging in freezing conditions

Maintain operational temperature within the optimal range

Store batteries at around 40–60% SOC for extended periods

Use a BMS with active balancing to prevent cell voltage imbalances

Avoid continuous high-load or rapid pulsed discharges unless the battery is rated for it

While LiFePO4 does not provide the highest energy density, it offers the best combination of longevity, thermal stability, and safety. Compared to other chemistries:

NMC/NCA Li-ion: Higher energy density but shorter cycle life and moderate thermal stability

Lead-acid: Low energy density and limited cycle life

LTO (Lithium Titanate): Extremely long cycle life but lower energy density

LiFePO4 batteries are ideal for applications requiring long-term, reliable energy storage with safe operation.

1. How long does a LiFePO4 battery last?

Typically, 2,000–6,000 cycles, which translates to approximately 8–15 years under moderate DoD and temperature control.

2. Does temperature significantly affect cycle life?

Yes. High heat accelerates chemical degradation, while very low temperatures can cause lithium plating and capacity loss.

3. What is the ideal DoD for long-term performance?

Operating at 50–80% DoD balances energy throughput and battery longevity effectively.

Ni-MH Battery C4700mAh 3.6V

Ni-MH Battery C4700mAh 3.6V Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V

Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V Ni-Cd Battery Pack D4000mAh 3.6V

Ni-Cd Battery Pack D4000mAh 3.6V Ni-Cd Battery Pack C2500mAh 3.6V

Ni-Cd Battery Pack C2500mAh 3.6V NICAD Battery Pack AA900mAh 3.6V

NICAD Battery Pack AA900mAh 3.6V LiFePO4 IFR18650 1600mAh 3.2V

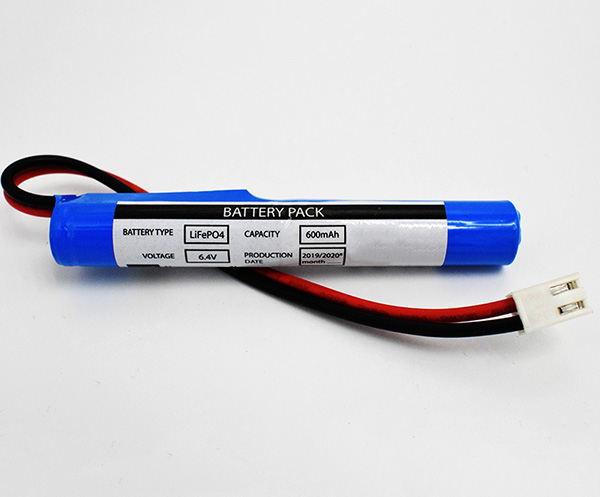

LiFePO4 IFR18650 1600mAh 3.2V LiFePO4 IFR18650 1600mAh 6.4V

LiFePO4 IFR18650 1600mAh 6.4V Ni-MH Battery C4000mAh 3.6V

Ni-MH Battery C4000mAh 3.6V E-bike Battery 48V 10Ah JL-1

E-bike Battery 48V 10Ah JL-1 E-bike battery 48V 10Ah Qing Tian

E-bike battery 48V 10Ah Qing Tian