As a Ni-MH Battery Pack Supplier, share with you.

1. Increase the specifications of lithium battery cells: A lithium battery pack is composed of hundreds of single lithium batteries connected in series. Lithium batteries are a key component of lithium battery pack control costs. At this stage, the key to reducing the cost of lithium battery products is to improve the raw material management system, enlarge the specifications of lithium batteries, and improve the quality of lithium batteries. In terms of large core diameter, at this stage, whether it is square, cylindrical or soft core diameter rechargeable batteries, there has been a development trend of single core diameter expansion. Its advantage is beneficial to improving the specific energy of lithium battery system software, reducing core diameter and controlling costs.

2. Lightweight structural parts: Lithium battery fine components, such as lithium battery core casing, machine cover, steel/aluminum casing, positive and negative conductive flexible connection, rechargeable battery conductive flexible connection bar, etc., although the cost is often accounted for in power lithium batteries The proportion is not large, but it has become the key to rechargeable battery manufacturers looking for price reductions.

Lithium Battery For Solar

Many manufacturers of lithium battery packs have introduced new materials and reasonable structural design solutions to reduce the net weight of new products by more than 20% compared with old products. In addition, they further reduce manufacturing costs, thereby reducing the overall cost of battery packs. In addition to the above components, auxiliary materials including housings and vehicle wiring harnesses are also key components of the immediate product cost of rechargeable battery companies.

3. BMS rechargeable battery intelligent management system: Compared with other raw materials, BMS rechargeable battery intelligent management system reduces the price more significantly. Many BMS company personnel indicated that the cost of BMS only accounts for 5%-10% of the price of lithium batteries, but because of the work pressure of subsidy decline, BMS companies will also encounter pressure to reduce prices. It is estimated that the price in 2018 may fall by more than 20% .

4. Improve the high efficiency of automation technology: Lithium battery pack manufacturing enterprises increase the production line automation production with high efficiency, and reduce enterprise manufacturing costs according to large-scale production. This is also an important way for power lithium battery companies to reduce product costs. In addition, according to the improvement of processing technology and production process, the completion of intelligent systems, import substitution production and manufacturing, increase the utilization rate of raw materials and yield, and greatly reduce the cost of lithium battery materials and PACK products.

Our company has Lithium Battery For Solar on sale, welcome to contact us.

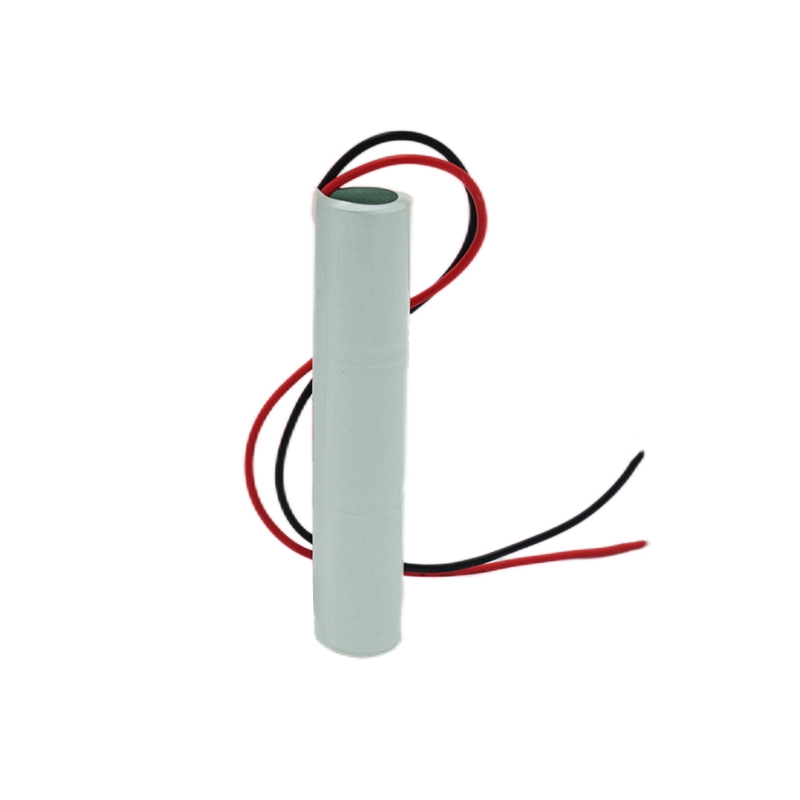

Ni-MH Battery C4700mAh 3.6V

Ni-MH Battery C4700mAh 3.6V Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V

Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V Ni-Cd Battery Pack D4000mAh 3.6V

Ni-Cd Battery Pack D4000mAh 3.6V Ni-Cd Battery Pack C2500mAh 3.6V

Ni-Cd Battery Pack C2500mAh 3.6V NICAD Battery Pack AA900mAh 3.6V

NICAD Battery Pack AA900mAh 3.6V LiFePO4 IFR18650 1600mAh 3.2V

LiFePO4 IFR18650 1600mAh 3.2V LiFePO4 IFR18650 1600mAh 6.4V

LiFePO4 IFR18650 1600mAh 6.4V Ni-MH Battery C4000mAh 3.6V

Ni-MH Battery C4000mAh 3.6V E-bike Battery 48V 10Ah JL-1

E-bike Battery 48V 10Ah JL-1 E-bike battery 48V 10Ah Qing Tian

E-bike battery 48V 10Ah Qing Tian