However, for lithium batteries, safety is a major concern for users and affects all stages of the supply chain, including transportation.

Today, there are a variety of different lithium-based chemistries on the market, each with its own characteristics and properties, making it more or less suitable for any specific application. Chemistry is not the only determining factor when it comes to defining the right performance of a lithium battery: this performance also stems from another important factor - the battery management system (BMS).

In fact, the BMS is able to fully exploit the properties of the chosen chemistry, ensuring reliability and long-term consistent performance by managing and controlling all the equipment surrounding the battery.

C-rate, thermal stability and specific energy are some of the characteristics related to the thermal risk or chemical, electrical and kinetic risks of the battery.

For these reasons, lithium batteries are classified as dangerous goods, the same as chemicals or flammables. Like any other material, they can be transported by all means, such as road, sea, rail or air.

However, since they are dangerous goods, they must be transported in accordance with specific regulations to ensure that they are properly handled and protected during the transportation and storage phases, avoiding unpleasant situations such as fire. It is for this reason that they are classified as "dangerous goods" and their handling, whether domestically or internationally, must comply with special European regulations and must use special transport packaging.

What are the "rules" that need to be followed and how can lithium batteries be transported safely?

Lithium Battery Transport and the requirements of the Manual of Tests and Criteria.

In terms of transport, lithium batteries can be transported by road, sea, rail or air if they are properly certified and specially packaged. However, medium and large batteries are not accepted cargo by airlines and are not allowed to be transported on cargo flights.

All commodities considered "dangerous" must meet specific requirements set out in the Manual of Tests and Criteria, an international document developed by the United Nations. This document contains all the regulations that must be followed to safely handle goods for transport, and section 38.3 of it sets out the specifications for lithium-ion batteries.

UN 38.3 certification is required for the safe handling of batteries in any mode of transport, whether domestic or international, except for prototypes or small-scale test series, in order to avoid penalties or customs detention and ensure that no hazards occur during transportation.

Battery UN38.3 Certification

Battery Safety Test UN 38.3

UN 38.3 is a test used to certify that batteries are suitable for all types of transport and ensure that they pass all optional tests required by the regulations.

To obtain UN 38.3 certification, lithium batteries must undergo a rigorous series of 8 different tests performed by an approved independent center to ensure the safety of battery packs and batteries during transportation.

Tests required by UN 38.3 include:

T1. Plateau Simulation Test

The test simulates an unpressurized aircraft area at an altitude of 15,000 meters. The battery is subjected to a pressure of 11.6kPa for more than 6 hours and should meet the requirements of mass loss, no leakage, no exhaust, no disassembly, no rupture, no fire, and a voltage retention rate of not less than 90%.

T2. Thermal Test

The battery is stored at +72° C for 6 hours and then at -40° C for 6 hours for a total of 10 cycles. The test can be performed in a single room or a thermal shock chamber.

T3. Vibration Test

A test that simulates the vibration that occurs during normal transportation.

T4. Shock Test

A test that simulates a battery being impacted by subjecting it to strong accelerations.

T5. External Short Circuit Test

Simulates a short circuit external to the battery where the terminals are shorted to understand how it reacts in the event of an accident.

T6. Impact Test

This test is only applicable to single primary and secondary cells. The test subjects the battery to a 9.1 kg impact and simulates the dropping of the package prior to shipping.

T7. Overload Test

Simulates an overload condition for a rechargeable battery by providing a charge current 24 times the manufacturer's recommended for 2 hours. The battery must then be monitored for 7 days to prevent fire or decomposition.

T8. Forced Discharge Test

A test that simulates a forced discharge condition to the full capacity of the battery.

Summary Test for Batteries: Battery Passport

Once it has been determined that a battery meets all criteria in Section 38.3 of the Manual of Tests and Criteria, in order to proceed with outbound logistics, it must be ensured that the supporting shipping documents and accompanying labels are correct and complete.

Transport company policies on transporting batteries

FedEx Express lithium battery transport information

DHL lithium battery transport information

U.S. Department of Transportation PHMSA lithium battery transport guide

49 CFR 173.185 U.S. lithium battery hazardous goods regulations

UPS Information on Shipping Lithium Batteries

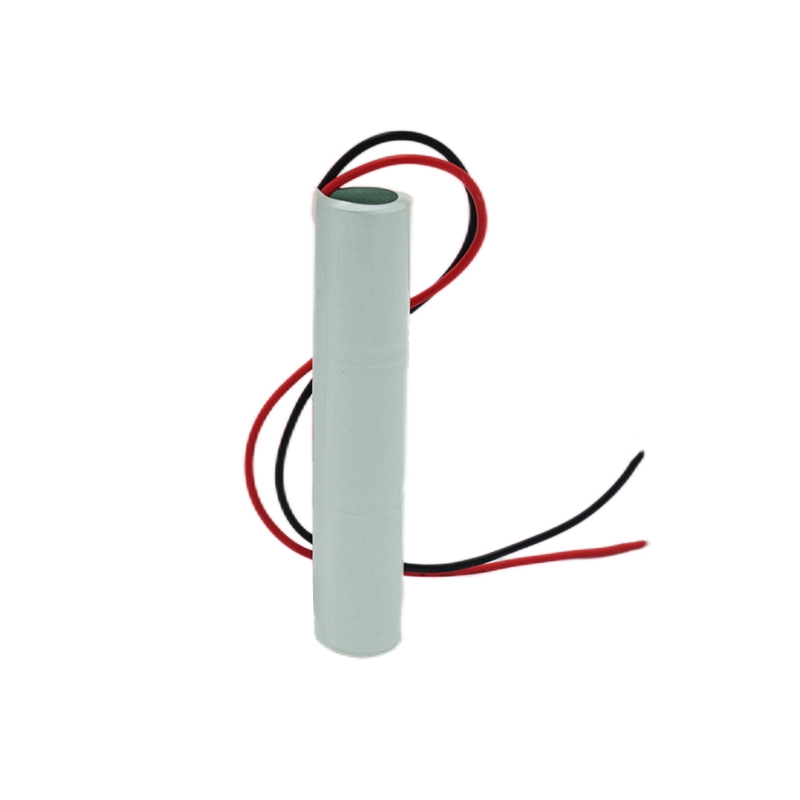

Ni-MH Battery C4700mAh 3.6V

Ni-MH Battery C4700mAh 3.6V Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V

Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V Ni-Cd Battery Pack D4000mAh 3.6V

Ni-Cd Battery Pack D4000mAh 3.6V Ni-Cd Battery Pack C2500mAh 3.6V

Ni-Cd Battery Pack C2500mAh 3.6V NICAD Battery Pack AA900mAh 3.6V

NICAD Battery Pack AA900mAh 3.6V LiFePO4 IFR18650 1600mAh 3.2V

LiFePO4 IFR18650 1600mAh 3.2V LiFePO4 IFR18650 1600mAh 6.4V

LiFePO4 IFR18650 1600mAh 6.4V Ni-MH Battery C4000mAh 3.6V

Ni-MH Battery C4000mAh 3.6V E-bike Battery 48V 10Ah JL-1

E-bike Battery 48V 10Ah JL-1 E-bike battery 48V 10Ah Qing Tian

E-bike battery 48V 10Ah Qing Tian