Nickel-based batteries may not always dominate conversations in today’s fast-moving energy storage industry, but they continue to hold strong relevance across multiple sectors. With lithium-ion batteries receiving much of the attention in recent years, it is easy to forget that Nickel-Cadmium (NiCd) and Nickel-Metal Hydride (NiMH) batteries remain essential where durability, reliability, and consistent performance are required.

Both chemistries have been integral to the development of rechargeable batteries for decades. Understanding their strengths, limitations, and how they compare with lithium-based options provides valuable insight for engineers, manufacturers, and users alike.

The Nickel-Cadmium battery is one of the earliest rechargeable technologies still widely used today. Constructed with nickel oxide hydroxide as the positive electrode and metallic cadmium as the negative electrode, NiCd batteries have long been valued for their toughness and ability to perform under demanding conditions. They are manufactured in both sealed and vented formats, making them suitable for a wide range of applications, including emergency lighting, aviation, power tools, and backup power systems.

Strengths of NiCd

Very low internal resistance, enabling fast energy transfer.

Capable of high charge and discharge rates, including up to 10C for short bursts.

Provide a flat discharge curve, ensuring stable voltage until the final stage.

Withstand deep discharges and repeated deep cycling.

Perform reliably across a broad temperature range, up to about 70°C.

Weaknesses of NiCd

Prone to the memory effect, reducing usable capacity over time.

Sensitive to overcharging, which can damage cells and shorten service life.

Pose environmental challenges due to cadmium content, requiring careful handling and recycling.

Even with these drawbacks, NiCd batteries remain the preferred choice in environments where safety, ruggedness, and reliability are more important than energy density.

Developed to address the environmental issues of cadmium, Nickel-Metal Hydride batteries use a hydrogen-absorbing alloy as the negative electrode instead of cadmium. This shift significantly improved energy density and reduced environmental risks, while maintaining many of the performance benefits associated with NiCd technology.

A single NiMH cell typically offers two to three times the capacity of an equivalent NiCd cell, though it still does not match the energy density of lithium-ion.

Strengths of NiMH

Approximately 70 Wh/kg energy density, around 50% higher than NiCd.

Typical cycle life of up to 3,000 cycles when properly managed.

Can tolerate deep discharges, often 80–100% depth of discharge.

More environmentally friendly, with no cadmium content.

Stable flat discharge profile throughout the cycle.

Robust against overcharge and over-discharge, reducing complexity in management systems.

Wide temperature tolerance, making them versatile for industrial use.

Weaknesses of NiMH

Relatively high self-discharge, losing energy more quickly during storage.

Still affected by the memory effect, though to a lesser extent than NiCd.

May deteriorate after long periods of inactivity, requiring reconditioning.

Can generate gas under stress, so safety vents are necessary.

Provide only 1.2 volts per cell, requiring multiple cells for higher-voltage applications.

Today, NiMH batteries are frequently used in medical equipment, hybrid vehicles, consumer electronics, and renewable energy storage, striking a balance between safety, capacity, and cost-effectiveness.

Although lithium-ion technology has taken the lead in many markets, nickel-based batteries still compete effectively in specialized areas. Here are five important distinctions:

Energy Density: Lithium-ion has the highest, but NiMH offers more than NiCd.

Durability: NiCd and NiMH outperform lithium-ion under extreme conditions.

Cycle Life: NiMH packs can last thousands of cycles with proper care.

Safety: Nickel-based batteries are more tolerant of overcharging and deep discharge, with lower risk of thermal runaway.

Environmental Impact: NiCd faces restrictions due to cadmium, while lithium-ion still faces challenges in recycling.

While lithium-ion dominates consumer electronics and electric vehicles, nickel-based chemistries continue to play an important role in specific applications where safety, reliability, and long-term durability are vital. Sectors such as medical technology, aerospace, industrial backup power, and emergency systems continue to rely on their proven performance.

Ongoing research into NiMH technology is aimed at reducing self-discharge, improving energy density, and extending service life, which could further strengthen its position in industries that require cost-effective and stable power solutions.

Nickel-Cadmium and Nickel-Metal Hydride batteries remain indispensable technologies in the modern energy market. Though lithium-ion sets new benchmarks for energy storage, nickel-based batteries continue to provide trusted, rugged, and safe solutions where performance cannot be compromised.

For critical applications, the right choice often depends on balancing energy density with reliability—and in many scenarios, nickel-based options remain the smarter solution.

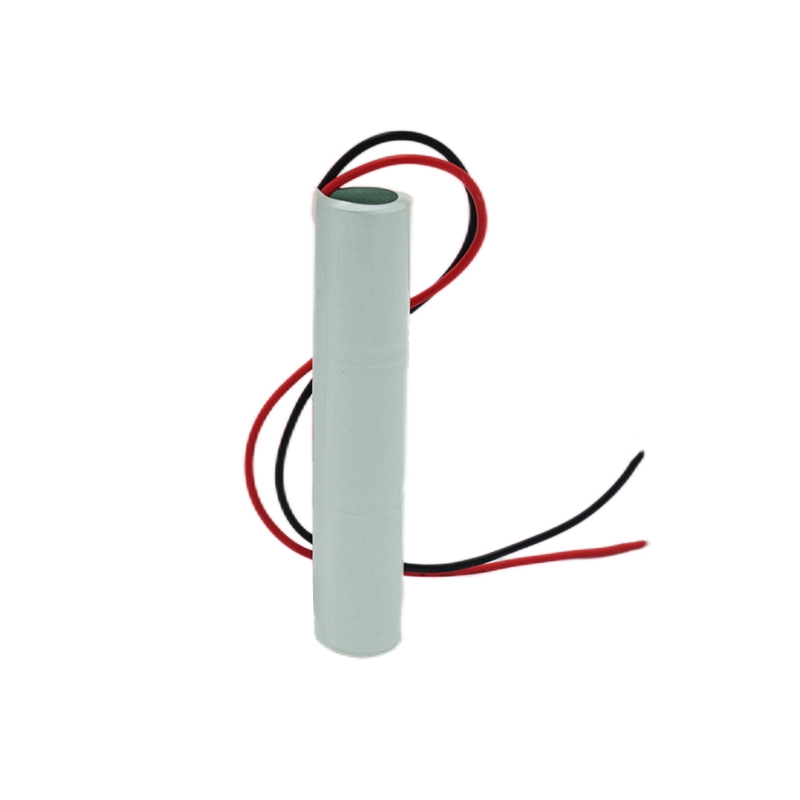

Ni-MH Battery C4700mAh 3.6V

Ni-MH Battery C4700mAh 3.6V Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V

Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V Ni-Cd Battery Pack D4000mAh 3.6V

Ni-Cd Battery Pack D4000mAh 3.6V Ni-Cd Battery Pack C2500mAh 3.6V

Ni-Cd Battery Pack C2500mAh 3.6V NICAD Battery Pack AA900mAh 3.6V

NICAD Battery Pack AA900mAh 3.6V LiFePO4 IFR18650 1600mAh 3.2V

LiFePO4 IFR18650 1600mAh 3.2V LiFePO4 IFR18650 1600mAh 6.4V

LiFePO4 IFR18650 1600mAh 6.4V Ni-MH Battery C4000mAh 3.6V

Ni-MH Battery C4000mAh 3.6V E-bike Battery 48V 10Ah JL-1

E-bike Battery 48V 10Ah JL-1 E-bike battery 48V 10Ah Qing Tian

E-bike battery 48V 10Ah Qing Tian