A typical lithium iron phosphate battery is composed of several key components, including:

Positive electrode (cathode)

Negative electrode (anode)

Electrolyte

Separator

Electrode leads (positive and negative)

Center terminal

Safety valve

Sealing ring

Outer shell

Cathode material: lithium iron phosphate with an olivine crystal structure, usually attached to an aluminum foil collector.

Separator: a thin polymer membrane positioned between the cathode and anode, allowing lithium ions (Li⁺) to pass while preventing electron flow.

Anode material: carbon (commonly graphite), connected to a copper foil collector.

The structural characteristics of the cathode material provide high thermal and chemical stability, although the intrinsic conductivity of the material is relatively low.

Charging process:

Lithium ions move from the lithium iron phosphate crystal surface into the electrolyte.

Driven by the electric field, the ions migrate through the separator and reach the graphite anode, where they are embedded into the graphite lattice.

Simultaneously, electrons flow from the cathode current collector (aluminum foil) through the external circuit to the anode current collector (copper foil), maintaining charge balance.

As lithium ions leave the lithium iron phosphate, the material transforms into iron phosphate.

Discharging process:

Lithium ions are released from the graphite lattice and pass through the electrolyte and separator.

They then migrate to the lithium iron phosphate cathode, where they re-enter the crystal lattice.

At the same time, electrons flow from the anode current collector through the external circuit back to the cathode collector, ensuring charge equilibrium.

This reversible migration of lithium ions between the cathode and anode, combined with electron flow in the external circuit, forms the basis of the battery’s energy storage and release mechanism.

Recommended Charging Method

The most suitable method for charging lithium iron phosphate (LiFePO4) battery packs is the constant current–constant voltage (CCCV) method.

Constant current stage (CC): recommended at 0.2C of the battery’s rated capacity.

Constant voltage stage (CV): recommended charging voltage is 3.65V per cell.

This two-step charging process helps ensure both efficiency and safety, extending the overall cycle life of the battery.

Difference Between LiFePO4 and Other Lithium-Ion Batteries

Both LiFePO4 batteries and conventional lithium-ion batteries use the CCCV charging method. However, the charging parameters are different:

LiFePO4 battery: nominal voltage 3.2V; charging cut-off voltage 3.65V.

Conventional lithium-ion battery: nominal voltage 3.6V; charging cut-off voltage 4.2V.

Because of this difference, chargers designed for other lithium-ion batteries are not always suitable for LiFePO4 cells without proper adjustment.

Can LiFePO4 Batteries Be Charged with Solar Power?

Solar panels cannot directly charge LiFePO4 batteries. Since the voltage output of solar panels fluctuates depending on sunlight conditions, a voltage regulation circuit and a dedicated charging controller are required to stabilize the current and voltage before charging.

Charging with a Generator

Similarly, generators cannot charge LiFePO4 batteries directly. Generator output is typically alternating current (AC) or pulsed direct current (DC), which is unsuitable for direct charging. A rectifier and regulator circuit must be used to convert the output into stable DC power before it can safely charge the battery.

When charging lithium iron phosphate (LiFePO4) batteries, different charging strategies can be applied depending on the application scenario and the balance between charging efficiency, safety, and cycle life. Below are four commonly used charging methods.

In this method, the charging power supply maintains a fixed output voltage. As the state of charge of the battery changes, the charging current automatically adjusts.

Advantages: ensures full charging if the voltage setting is correct, and minimizes gas generation or electrolyte loss.

Disadvantages: charging current at the beginning can be excessively high, which may damage the battery. Since only the battery voltage is considered, this method cannot accurately reflect the overall charging state.

For these reasons, constant voltage charging is rarely used as a standalone method.

Here, the charging current remains constant by adjusting the voltage output of the charger.

Advantages: simple control, convenient operation, easy to implement, and charging capacity can be calculated easily.

Disadvantages: as the battery approaches full charge, its ability to accept current decreases. This leads to a reduced charging efficiency in the later stage.

This method is often used in the initial charging phase but is not ideal for completing the entire charging cycle.

This is the most widely adopted charging strategy for LiFePO4 batteries, combining the strengths of both methods above.

Stage 1: Constant current charging – prevents excessive inrush current and ensures efficient charging in the early phase.

Stage 2: Constant voltage charging – controls the charging voltage and prevents overcharging, which could damage the battery.

By combining both steps, this method provides a safer and more efficient charging process, extending the cycle life of LiFePO4 batteries.

In this method, the current is delivered intermittently: the charging current flows for a set time, then stops, and the cycle repeats.

Advantages: allows ions inside the battery to diffuse during the rest periods, improving charge acceptance and utilization rate.

Effect: provides the battery with a “relaxation” or “digestion” time, reducing stress on the electrodes and enhancing charging efficiency.

This method is often used to optimize performance in specific applications where extended battery life and efficiency are prioritized.

Proper discharging is essential to maintain the performance and cycle life of a LiFePO4 battery. Below are the key steps to follow.

The maximum recommended discharge rate for LiFePO4 batteries is generally 1C to 3C.

1C rate: the battery can be fully discharged in 1 hour.

3C rate: the battery can be fully discharged in one-third of an hour.

Exceeding these limits may lead to overheating, reduced lifespan, or even battery damage.

Attach the battery to the device or load that will consume the power.

Ensure that all connections are secure and that polarity is correct (positive to positive, negative to negative). Improper connections can cause short circuits or damage.

Use a voltmeter or a battery management system (BMS) to track voltage during discharge.

Never allow the cell voltage to drop below 2.5V per cell, as overdischarge can cause irreversible damage.

Keep the discharge within the safe 1C–3C range.

If the battery becomes unusually warm during operation, reduce the discharge current to avoid thermal stress.

End the discharge process when the voltage reaches 2.5V per cell.

Going below this limit can result in permanent capacity loss or internal degradation.

After use, store the LiFePO4 battery in a cool, dry place.

Avoid keeping it fully charged or fully discharged for long periods.

The ideal storage condition is around 50% state of charge (SOC) to balance safety and longevity.

LiFePO4 battery packs are formed by connecting multiple single cells in series and parallel. Because of this configuration, the consistency of individual cells is critical: if even one cell performs differently, the overall efficiency and lifespan of the pack will be reduced.

The cycle life of a LiFePO4 battery depends on multiple factors, including material quality, specifications, frequency of use, charging and discharging methods, and maintenance practices. Following the guidelines below can help maximize performance and extend service life.

Do not charge the battery beyond 80% capacity or discharge it below 20% capacity.

A practical rule is to recharge the battery when it drops to about 30%, and maintain operation between 40–80% state of charge (SOC).

This helps slow down capacity degradation and prolongs cycle life.

Charging time should not be excessively long.

Always disconnect power once the battery is fully charged to prevent stress from overcharging.

Regularly wipe dust and debris from the surface of the battery.

Prevent contaminants from entering connection points, as they may impact performance and shorten service life.

Operating or storing LiFePO4 batteries in very high or low temperatures will shorten lifespan.

The recommended working temperature range is 5°C to 35°C.

Avoid leaving the battery in direct sunlight, freezing environments, or enclosed spaces with poor ventilation.

The casing of LiFePO4 batteries is relatively thin, so they must be protected from heavy pressure, impacts, or bending.

Mechanical stress may cause deformation or internal short circuits.

Inspect and tighten battery connectors.

Clean the terminals and check for corrosion or loose wiring.

Regular upkeep ensures safe operation and stable performance.

Always use a charger specifically designed for LiFePO4 batteries.

Mismatched voltage or current from an incompatible charger can damage cells and shorten lifespan.

Avoid mixing old and new batteries or using chargers meant for other lithium chemistries.

Ni-MH Battery C4700mAh 3.6V

Ni-MH Battery C4700mAh 3.6V Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V

Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V Ni-Cd Battery Pack D4000mAh 3.6V

Ni-Cd Battery Pack D4000mAh 3.6V Ni-Cd Battery Pack C2500mAh 3.6V

Ni-Cd Battery Pack C2500mAh 3.6V NICAD Battery Pack AA900mAh 3.6V

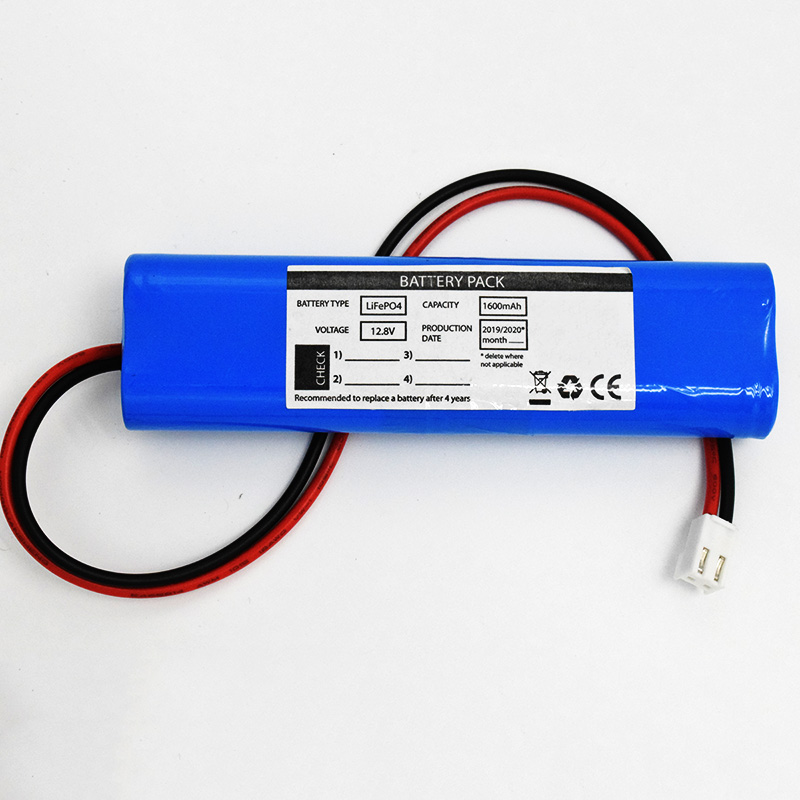

NICAD Battery Pack AA900mAh 3.6V LiFePO4 IFR18650 1600mAh 3.2V

LiFePO4 IFR18650 1600mAh 3.2V LiFePO4 IFR18650 1600mAh 6.4V

LiFePO4 IFR18650 1600mAh 6.4V Ni-MH Battery C4000mAh 3.6V

Ni-MH Battery C4000mAh 3.6V E-bike Battery 48V 10Ah JL-1

E-bike Battery 48V 10Ah JL-1 E-bike battery 48V 10Ah Qing Tian

E-bike battery 48V 10Ah Qing Tian